CNC Machining

What is CNC machining?

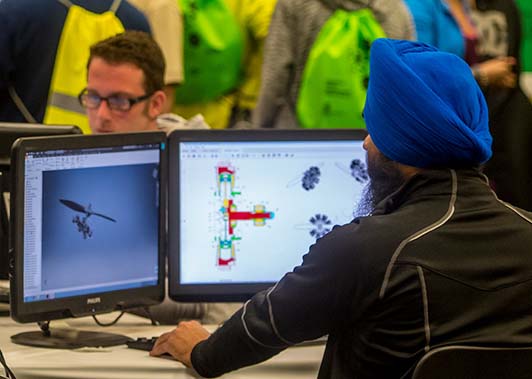

Computer numerical control (CNC) technology is used by machinists to operate a variety of manufacturing tools and equipment in the production of metal parts. These parts must be made to exacting standards, and the machinist uses precision measuring instruments to ensure accuracy and that the parts meet quality guidelines. A machinist reads and interprets specifications and blueprints, calculates dimensions and tolerances, lays out their work and marks pieces for machining. They then set up, program and operate their machine tools, such as CNC metal turning lathes, to cut or grind the metal into parts or products to the precise specifications of engineers or designers. They fit and assemble the machined metal parts and subassemblies, and verify their dimensions, strength and hardness.

The job of the machinist has changed due to technical advances such as the development of CNC technology. Now more than ever, it combines mental ability with manual skills – to develop a project from a blueprint requires careful thought and an understanding of mathematics and computer programming, as well as good mechanical ability. However, modern computer age machinists must still understand the properties of metal and basic manual machining techniques as they rely on this knowledge to set up and operate the variety of machine tools they use.

Machining tool operators perform some or all of the following duties:

- Study job orders and interpret blueprints to determine machining operations to be performed

- Set up and operate machine tools to perform repetitive machining operations, such as turning, milling, drilling, boring, planing, honing, broaching, grinding or other machining operations

- Verify dimensions of parts machined using micrometers, callipers and other precision measuring instruments

- Prepare etching solution and immerse metal parts or workpiece in etching solution to remove unwanted portions

- Perform routine maintenance on equipment and machinery

- May enter codes specifying speed, feed and cut of the toolpath for computer numerical controlled (CNC) machine tools.

HOW TO JOIN THE FIELD

- Some secondary school education is required.

- College or other courses in machining may be required.

- Several months of on-the-job training are provided.

- Senior positions in this unit group, such as set-up operator, require experience as a machine operator.

INDIGENOUS AND REMOTE CONSIDERATIONS

Many Indigenous and remote communities do not have the same access to information and experience when it comes to science, mathematics and technology fields. This would likely mean that students from these communities may need extra support when they are pursuing this field both in post-secondary school, as well as on-the-job.

Indigenous and remote communities are catching up to southern Canada when it comes to digital technology and computer skills and industries. Not all communities have access to reliable, affordable internet and service interruptions are all too common. Access to computers at home is not a given for everyone and Elders and even sometimes younger generations lack computer knowledge, although this situation is undergoing some significant changes at the moment. But even those people in Indigenous and remote communities with interest and high-level skills in computers may not have the same access to opportunities to learn about different programs and may face significant bandwidth issues, limiting their ability to learn and develop in this field. Indigenous and remote students may need qualifying courses or need to augment college learning to be successful in this field.

Although with significant improvements currently underway to internet connections in Indigenous and remote communities, careers in this field become more viable and are likely to become more so in years to come.

DISABILITY CONSIDERATIONS

As this field involves both complex thinking and analysis as well as physical operation, people with physical, intellectual and learning disabilities may need accommodations in order to be successful.

Find the right career path for you with our interactive map!

Trouvez le cheminement de carrière qui vous convient grâce à notre carte interactive!

Sample Job Titles

- Tool and die maker

- Machining and tooling inspector

- Machine tool set-up operator

- Aircraft parts etcher

- Boring mill operator

- Lathe machining operator

Companies and Sectors

- Manufacturing industry

- Transport industry

- Trade industry

CNC Machining and the Skills for Success Program

The key Skills for Success for this career path are:

- Numeracy

- Reading

- Collaboration